Quick Look

Grade Level: 5 (3-5)

Time Required: 30 minutes

Lesson Dependency: None

Subject Areas: Problem Solving

NGSS Performance Expectations:

| 3-5-ETS1-1 |

Summary

Students learn how engineering design is applied to solve healthcare problems by using an engineering tool called simulation. While engineering design is commonly used to study and design everything from bridges, factories, airports to space shuttles, the use of engineering design to study healthcare administration and delivery is a relatively new concept.Engineering Connection

Though at its core healthcare is all about biology and chemistry, the actual delivery and administration of healthcare via a complex network of doctors, hospitals and laboratories is an engineering problem. Established engineering tools, such as simulation, which has been used effectively to find solutions to global manufacturing and distribution problems, can be put to use to improve healthcare.

Learning Objectives

After this lesson, students should be able to:

- Explain how simulation can be applied to improve healthcare.

- Define simulation and explain its use in the testing step of the engineering design process.

- Apply simulation to solve a healthcare delivery problem.

- Define a simple design problem that includes specified constraints on materials, time, or cost.

Educational Standards

Each TeachEngineering lesson or activity is correlated to one or more K-12 science,

technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in TeachEngineering are collected, maintained and packaged by the Achievement Standards Network (ASN),

a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics;

within type by subtype, then by grade, etc.

Each TeachEngineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards.

All 100,000+ K-12 STEM standards covered in TeachEngineering are collected, maintained and packaged by the Achievement Standards Network (ASN), a project of D2L (www.achievementstandards.org).

In the ASN, standards are hierarchically structured: first by source; e.g., by state; within source by type; e.g., science or mathematics; within type by subtype, then by grade, etc.

NGSS: Next Generation Science Standards - Science

| NGSS Performance Expectation | ||

|---|---|---|

|

3-5-ETS1-1. Define a simple design problem reflecting a need or a want that includes specified criteria for success and constraints on materials, time, or cost. (Grades 3 - 5) Do you agree with this alignment? |

||

| Click to view other curriculum aligned to this Performance Expectation | ||

| This lesson focuses on the following Three Dimensional Learning aspects of NGSS: | ||

| Science & Engineering Practices | Disciplinary Core Ideas | Crosscutting Concepts |

| Define a simple design problem that can be solved through the development of an object, tool, process, or system and includes several criteria for success and constraints on materials, time, or cost. Alignment agreement: | Possible solutions to a problem are limited by available materials and resources (constraints). The success of a designed solution is determined by considering the desired features of a solution (criteria). Different proposals for solutions can be compared on the basis of how well each one meets the specified criteria for success or how well each takes the constraints into account. Alignment agreement: | People's needs and wants change over time, as do their demands for new and improved technologies. Alignment agreement: |

International Technology and Engineering Educators Association - Technology

-

Identify and collect information about everyday problems that can be solved by technology, and generate ideas and requirements for solving a problem.

(Grades

3 -

5)

More Details

Do you agree with this alignment?

-

Apply the technology and engineering design process.

(Grades

3 -

5)

More Details

Do you agree with this alignment?

State Standards

Florida - Science

-

Recognize and explain that science is grounded in empirical observations that are testable; explanation must always be linked with evidence.

(Grade

5)

More Details

Do you agree with this alignment?

-

Recognize and explain that when scientific investigations are carried out, the evidence produced by those investigations should be replicable by others.

(Grade

5)

More Details

Do you agree with this alignment?

Introduction/Motivation

How does an engineer design something? (Listen to the various student answers.)

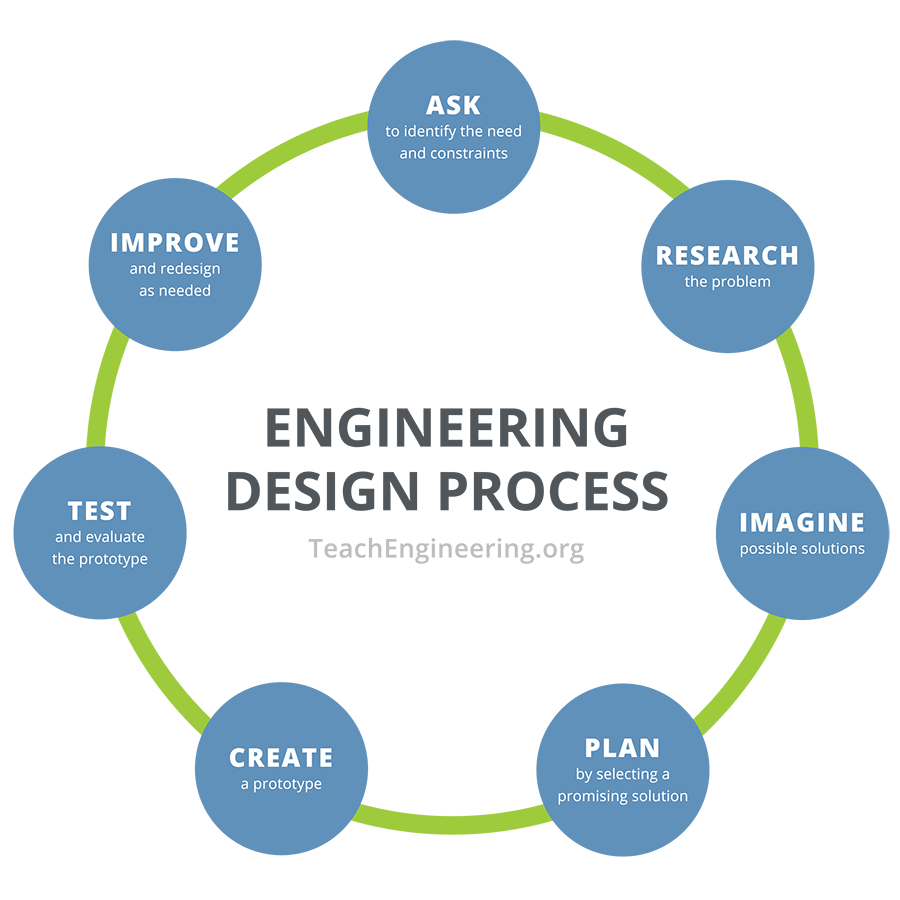

Let's take the example of creating a new car, and we'll follow through all of the steps of the engineering design process. Step 1 is to "Ask: define the needs and constraints." (Write this on the board; refer to Figure 1.) Older cars use a lot of gas to get places, so let's decide that our challenge is to make a new car that uses less fuel. Without knowing it, we have defined a design constraint (a limitation or restriction on our design). Our new car cannot use any amount of fuel. Instead, it needs to use as little fuel as possible. In fact, in the real world, the constraint on fuel consumption would actually be a quantitatively defined (i.e. must get 40+ miles to the gallon). What are some other design constraints a car engineering might have to work under? (Listen to the various student answers). We have now completed Step 1.

After defining the problem, engineers spend a long time doing background research, Step 2 of the engineering design process. They need to know what people already know about the topic, so that they do not try the same things that have already been attempted. What can they do differently that people have not already done before? What has been unsuccessful in the past? What did we learn from what was done in the past? What important information does the engineer need to know? For our car, the engineers need to ask themselves: what types of cars have already been made? And, why do they use gas?

Once engineers have learned everything they can about the topic, they establish the design criteria—that is, the rules guiding the design process for this challenge. For example, we need to decide which parts of the car we want to focus on. Are we going to change the wheels or the engine? Let's change the engine in our car.

Now that we know what we want to fix, we can start imagining some initial designs. These are called preliminary, and we don't know how well they will work yet. After this, comes actual testing of the preliminary design. We really need some creativity at this stage. How can we complete ours tests on our designs? Should we just build our new car and hope that it runs? Or do we build several cars and pick the one that works the best? Many times it is easier to make a model of what we want to build or change. The model resembles the real thing. Then, we can try our tests on the model, and not actually change the real thing. This is called simulation. Once we have the results of our simulation, we analyze our data, redesign and retest if necessary, and report our results and recommendations based on what we have learned.

Lesson Background and Concepts for Teachers

We use simulation (and model building, called modeling) as part of the testing step in engineering design. Running tests on a simulation model rather than on a real system is less time consuming, less disruptive, and less expensive. Once the results of the simulation are obtained, we analyze the data, verify, redesign and retest, and write reports and recommendations that will later be implemented in the real system.

Modeling and simulation:

- Instead of testing on an actual system, a model is tested. When we test different real-life situations (often called systems) with the help of a model, we are performing a simulation. The connection between real-life situations and simulation models is illustrated in Figure 2.

- A simulation allows us to test changes in systems that are difficult, or expensive to change.

- When we create our model, we must decide what is and what is not important to include. We want to make our model sufficient for our experiment, but not too complicated or expensive.

- When conducting a simulation, the model must first be tested without any changes. This ensures that the model mimics the real-life situation.

The use of simulation instead of actual tests in manufacturing is not a new idea. However, its use to model healthcare delivery is not widespread. Healthcare is a complicated area that deals with people and their emotions.

Healthcare:

- Healthcare includes more than just a visit to the doctor. Healthcare is a system that includes many components (see Figure 3), such as billing and insurance, the design of the facility, laboratories and other equipment, medicine, physicians, technicians, nurses and other healthcare employees, not to mention patients.

- The healthcare system includes a range of diverse processes, perhaps beginning with a 911call, all the way until that patient is discharged from the hospital (see Figure 4).

- Costs of healthcare delivery are broken down into many sections as well. Administrative costs make up a large portion of the cost of healthcare. These costs include billing, patient tracking, and many other costs. A large part of the patient's experience is waiting! Refer to the associated activity At the Doctor's where students simulate a doctor's office with the objective to improve the patient waiting time.

Associated Activities

- At the Doctor's - In this simulation of a doctor's office, students play the roles of doctor, nurse, patients, and timekeeper, with the objective to improve the patient waiting time. They collect and graph data as part of their analysis.

Vocabulary/Definitions

constraint: A limitation or restriction.

healthcare: All processes, people and facilities used to medically treat individuals.

manufacturing: The processes used to convert raw materials into products.

model: An object that resembles the real thing, but usually less expensive and/or smaller than the actual object.

run: Completing the simulation one time, similar to a trial in an experiment.

simulation: Using a model that replicates a real-life situation for use in an experiment.

Assessment

Pre-Lesson Assessment Questions: Ask students the following questions:

- What is healthcare? (Possible answer: All the people, processes and equipment used to treat people for their medical needs.)

- What could we do if we want to study a situation but we cannot perform an experiment on the real thing? (Possible answer: We can create a model and conduct tests on the model. This is called simulation.)

- What are some possible constraints that engineering, designing technology for health care, might run into? (Possible answers: money, time, keeping the hospital running while integrating the new technology, etc.)

- In what step of the engineering design process do engineers use simulation? (Answer: Simulation is used in the testing step because it allows us experiment with making changes on a model without changing the real thing.)

Homework & Discussion: Ask students to write short reports in response to the scenario and questions below. Require that they include information gathered from the Internet about how to solve these problems (sample problem: waiting time). The next day, lead a class discussion in which students share their answers.

Scenario: Write a short report describing a time you went to a doctor's office for health care. As part of the report, answer the following questions:

- Did you have to wait in the waiting room before you were seen by the doctor? (Possible answer: "While at the office, I waited 25 minutes before I saw the doctor." Follow-up questions: Why do you think it took so long [or was so quick]? Did you see a lot of people waiting to be seen by the doctor? What other people [such as nurses and assistants] were helping at the doctor's office? What were their responsibilities?)

- Did you see any problems during your visit? (Possible answer: "I saw a patient receive the wrong medicine." or "Somebody came in who was very sick and we had to wait longer." If the students did not see any problems, ask: What situation(s) might arise that would cause problems at the doctor's office?)

- If you saw problems, describe what happened? How do you think these problems can be solved using engineering? Be sure to indicate possible constraints and how your engineering design solution stays within those constraints. (Student answers will vary. Lead the discussion by comparing a doctor's office to the making of a new car or an improved product, and how engineers can help solve design problems in both. For example, at a doctor's office we might want to reduce waiting time or increase the number of patients a doctor sees during the day. At a car manufacturing plant, we might want to build cars that consume less gas and are safer. In both situations, engineers come up with solutions. In the doctor's office case, engineers might suggest scheduling patients based on the severity of their illnesses, or suggest adding an additional nurse and/or computers to speed up the administrative procedures. In the car manufacturing case, engineers might suggest using a new type of engine design or changing the materials used to manufacture the car.)

Lesson Extension Activities

Engineers also conduct simulations to replicate physical conditions, such as earthquake shaking conditions. They make shake tables and test structural designs and materials for earthquake resistance. To learn more, conduct the Shake It Up! Engineering for Seismic Waves activity.

Subscribe

Get the inside scoop on all things TeachEngineering such as new site features, curriculum updates, video releases, and more by signing up for our newsletter!More Curriculum Like This

Students learn about the basics of molecules and how they interact with each other. They learn about the idea of polar and non-polar molecules and how they act with other fluids and surfaces. Students acquire a conceptual understanding of surfactant molecules and how they work on a molecular level. ...

References

Allen. GruntDoc: Ramblings of an Emergency Physician in Texas. Accessed November 1, 2011. http://gruntdoc.com/

CHEMIE.de (operates scientific internet portals) Accessed November 1, 2011. http://www.chemie.de/

ER Fast Track for Minor Emergencies. North Shore Medical, Tenet HealthSystem, Miami, FL. Accessed November 1, 2011. http://www.northshoremedical.com/EN-US/OURSERVICES/MEDICALSERVICES/Pages/ERFastTrackforMinorEmergencies.aspx

Haleyville – The First 911 Call (placed February 16, 1968). Dispatch Magazine On-Line. Accessed November 1, 2011. http://www.911dispatch.com/911/history/haleyville_album.html

Maria, Anu. "Introduction to Modeling and Simulation," Proceedings, 1997 Winter Simulation Conference (29th), ed. S. Andradóttier, K.J. Healy, D.H. Withers, and B.L. Nelson. IEEE Computer Society, pps 7-13. Accessed November 1, 2011. http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.81.8350&rep=rep1&type=pdf

Other Related Information

(optional: Show students the What Is Engineering? video)

Copyright

© 2013 by Regents of the University of Colorado; original © 2011 College of Engineering, University of South FloridaContributors

Courtney Feliciani (under the advisement of Patricio Rocha, Dayna Martinez and Tapas K. Das)Supporting Program

STARS GK-12 Program, College of Engineering, University of South FloridaAcknowledgements

This curriculum was developed by the USF Students, Teachers and Resources in Sciences (STARS) Program under National Science Foundation grant numbers DGE 0139348 and DGE 0638709. However, these contents do not necessarily represent the policies of the NSF, and you should not assume endorsement by the federal government.

Last modified: July 21, 2020

User Comments & Tips